Types of Industrial Oven

- Industrial Tunnel Ovens

- Industrial Batch Ovens

- Conveyor Ovens

- Convection Oven

- Infrared Cure Oven

- Gas Convection Ovens

- Electric Convection Ovens

- Powder Coating Oven

Industrial Tunnel Ovens

Tunnel ovens and tunnel furnace systems are available in a variety of heat sources including infrared / convection combination, direct gas fire, gas-fired convection, electric infrared, electric convection, and other heat sources best suited to your process. Each tunnel oven is designed for your specific application and can be designed to include multiple heat and cooling zones.

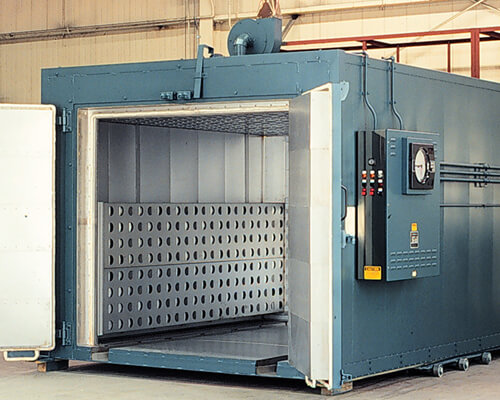

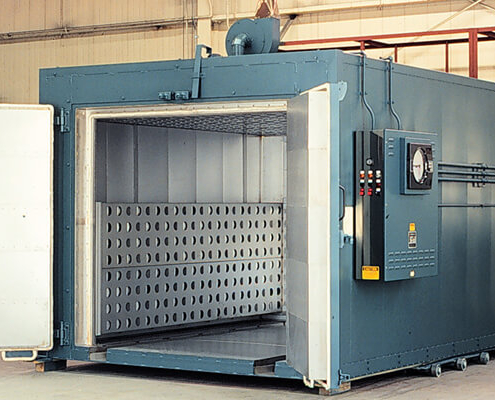

Industrial Batch Oven

Tunnel ovens and tunnel furnace systems are available in a variety of heat sources including infrared / convection combination, direct gas fire, gas-fired convection, electric infrared, electric convection, and other heat sources best suited to your process. Each tunnel oven is designed for your specific application and can be designed to include multiple heat and cooling zones.

Conveyor Oven

A conveyor oven is a continuous flow oven; it‘s an oven that is open on opposing sides and has a conveying system running from one end of the oven to the other. Designed like a batch oven, conveyor ovens have the additional benefit of keeping products moving while providing continuous and uniform heat. They are ideal for mass production and massive product runs.

Convection Oven

A convection oven has a fan and exhaust system that circulate hot air around the cavity of the oven, reducing hot and cool spots and helping dishes on every rack cook more evenly. Convection ovens can also have a third heating element, called true convection, to help foods cook faster.

Infrared Cure Ovens

Infrared heating is accomplished by electrical energy being generated in infrared wavelengths emitted from the surface of the heating element. The heat waves travel continuously until they make contact with an object. With an infrared conveyor oven, infrared heating is an efficient and homogeneous method for heating products.

Gas Conveyor Ovens

Gas-heated conveyor ovens have burners above and below the conveying mechanism. For improved uniform heating, a gas and air mixture is supplied to the burners, which are ignited by a spark electrode. Heat is transferred from the gas flames, the oven top, base, and walls by radiation. The burners operate on zero gas pressure with air supplied by blowers. The belt is made of woven wire mesh or heavy meshed steel.

Electric Convection Ovens

The key factor for an electric convection conveyor oven is the continuous circulation of the heated air by a fan or other source. The circulating mechanism pulls air from one section of the oven and pushes it back into the oven. The process maintains uniform temperature throughout the heated space and brings more heated air into contact with the elements being treated.

Powder Coating Oven

Powder coating protects materials from distinctive influence. It provides an even surface and a constant finish. Thermoset or thermoplastic is used and granulated into a powder form. The powder is then sprayed onto the surface of a metal body using an electric charge and then this surface needs to be cured.

https://www.vasanenterprises.com/wp-content/uploads/2022/08/Stainless-Steel-Fabrication-Services-in-Chennai.jpg

400

500

bestcool_vasan

https://www.vasanenterprises.com/wp-content/uploads/2022/05/logo.png

bestcool_vasan2022-08-30 08:47:012022-10-15 06:19:26Stainless Steel Fabrication Services in Chennai

https://www.vasanenterprises.com/wp-content/uploads/2022/08/Stainless-Steel-Fabrication-Services-in-Chennai.jpg

400

500

bestcool_vasan

https://www.vasanenterprises.com/wp-content/uploads/2022/05/logo.png

bestcool_vasan2022-08-30 08:47:012022-10-15 06:19:26Stainless Steel Fabrication Services in Chennai